Ne pas vendre ou partager mes informations personnelles

Comme indiqué dans notre politique de confidentialité, nous collectons vos données personnelles issues de vos interactions avec notre site web, notamment via l’utilisation des cookies et technologies similaires. Ces informations peuvent être partagées avec des tiers, y compris des partenaires publicitaires. Nous procédons ainsi afin de vous présenter des publicités sur d'autres sites web qui correspondent mieux à vos intérêts et pour d'autres raisons détaillées dans notre politique de confidentialité.

Nous sommes conscients que le partage de données personnelles à des fins publicitaires ciblées basé sur votre navigation peut être considéré comme une « vente », un « partage » ou de la « publicité ciblée » selon les lois relatives à la confidentialité en vigueur dans certains États américains. Selon votre lieu de résidence, vous disposez donc probablement d'un droit d'opposition à ces activités. Si vous souhaitez exercer ce droit, nous vous invitons à suivre les instructions ci-dessous.

Si vous visitez notre site web après avoir activé le paramètre de désactivation du Contrôle de confidentialité global, selon votre lieu de résidence, nous considérerons cela comme une demande de ne pas participer aux activités pouvant être considérées comme une « vente » ou un « partage » d'informations personnelles ou à toute autre utilisation pouvant être considérée comme de la publicité ciblée, pour l'appareil et le navigateur que vous avez utilisés pour accéder à notre site.

Fiberlogy PA12-CF15

The PA12+CF presents another facet of the technical capabilities of the PA12 filament, which has been further enhanced by the addition of 15% long carbon fiber.

It has high thermal resistance and reduced shrinkage compared to unmodified Nylon PA12. The use of carbon fiber reduces the weight of the component while maintaining its high structural rigidity.

The PA12+CF will be used in the automotive industry and engineering for the creation of advanced prototypes, drones and end products requiring increased durability and reduced weight.

It is currently the filament most used by BRS-Engineering, due to its quality, mechanical and thermal versatility and regularity.

Due to the longer fibers inside the PA, part has a specific grain on the surface finish, compared to a PCCF with CF powder. This contribute to the very high tensile resistance of this material.

*The composite materials printed by BRS-ENGINEERING follow a drying + annealing treatment in systematically controlled environment.

Price: +++

Polymaker PA6CF15

PolyMide PA6-CF is a carbon fiber reinforced PA6 (Nylon 6) filament. Carbon fiber reinforcement greatly improves stiffness, strength and heat resistance with exceptional layer adhesion.

Compared to PA12-CF15, It offers superior hardness and mechanical and thermal resistance. Actually the higher temp resistance polymer available at BRS before PS, PEKK and PEEK ranges.

BRS-Engineering, all PA6 are annealed to increase the intrinsic mechanical resistances

*Turn composite materials printed by BRS-ENGINEERING follow a drying + annealing treatment in systematically controlled environment.

Price: ++++

Fiberlogy PA12-GF15

PA12+GF15 is a derivative of Nylon PA12. It is reinforced by the incorporation of long fiberglass (GF), which represents 15% of the product. This addition significantly increases its toughness, stiffness, and thermal and chemical resistance compared to pure nylon.

The PA12+GF15 has a stiffness of 3.6 GPa and a temperature resistance up to about 170°C.Unlike nylon with the addition of carbon fibers, PA12+CF15, this filament offers greater flexibility, which makes it perfect for applications operating under variable loads and exposed to shocks.

The very low shrinkage ensures high dimensional stability, which, combined with high toughness, Achieves technical excellence in domestic conditions.

This filament does not require a heated chamber. However, due to the high abrasiveness, steel or ruby nozzles must be used for printing to avoid excessive wear. *The composite materials printed by BRS-ENGINEERING follow a drying + annealing treatment in systematically controlled environment.

Price: +++

Fiberlogy ASA

Thanks to its resistance to UV rays, high temperatures and humidity, ASA is a perfect choice for all 3D printing applications that can be exposed to different weather conditions.

The high mechanical and thermal resistance (even up to 94°C) as well as the ease of printing make this material the successor of ABS, ensuring its popularity in the automotive sector and in the production of everyday objects.

Contraction significantly lower than ABS, ASA (acrylonitrile styrene acrylate) deforms significantly less, it also has good stability of printing dimensions.

Price: ++

Prusament PCCF

Prusament PC Blend Carbon Fiber (PCCF) is a PC Blend filled with carbon fibers to improve its strength, toughness and temperature resistance. Unlike the unmodified PC Blend, PCCF comes with great dimensional stability, good resistance to UV light and common chemicals, better tensile strength and toughness, but most importantly with high-temperature resistance.

Chopped carbon fibers beeing more tiny, and PC vs PA specifications, it has a less tensile resistance and temperature resistance than the PA12CF15, PA6CF and PA12GF, on the other hand the finer shopped carbon fibers offers a smoother surface finish than those materials

Price: ++++

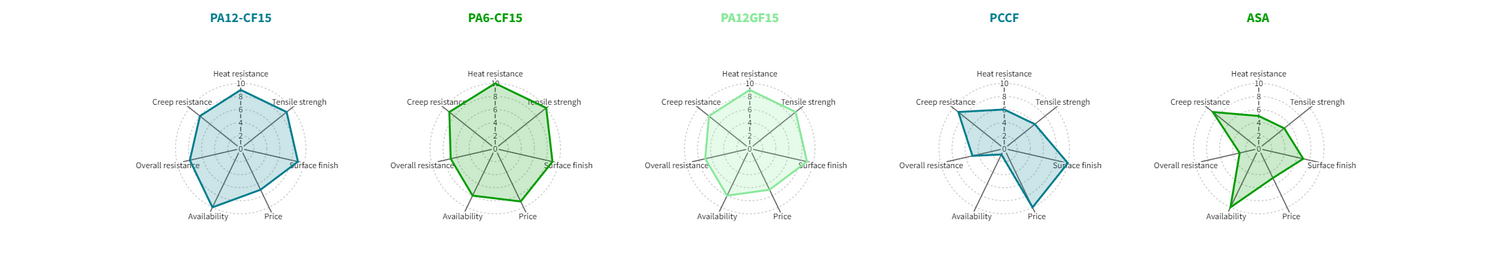

Battle of composites, what to choose? Sorted from High to low

-

Heat resistance

- PA6CF +++++

- PA12CF ++++

- PA12GF ++++

- PCCF ++

- ASA +

-

Tensile str

- PA6CF +++++

- PA12CF ++++

- PA12GF ++++

- PCCF ++

- ASA +

-

Surface finish

- PCCF +++++

- PA6CF +++

- PA12CF +++

- PA12GF +++

- ASA ++

-

Price

- PCCF ++++

- PA6CF ++++

- PA12CF +++

- PA12GF +++

- ASA ++

-

Availability

- ASA +++++

- PA12CF ++++

- PA12GF ++++

- PA6CF ++

- PCCF +

-

Overall resistance

- PA12CF ++++

- PA6CF +++

- PA12GF +++

- PCCF ++

- ASA +