Vulcain v1.4 820 Build log

Build log of the Vulcain 800, a printer designed from a Vcore achitecture with all BRS mods and specific improvment!

Objective of the build

-

Reliability

Only made of high quality hardware with a quality build assembly made at BRS-ENGINEERING. Aluminium brushed plates, Blind joined frame

-

Production focused

Ballscrews set to gain repetability, low maintenance, and high precision. All metal build for the toolhead, the frame and the gantry, PA12CF parts for durability

-

Big Volume

820x820x800mm

-

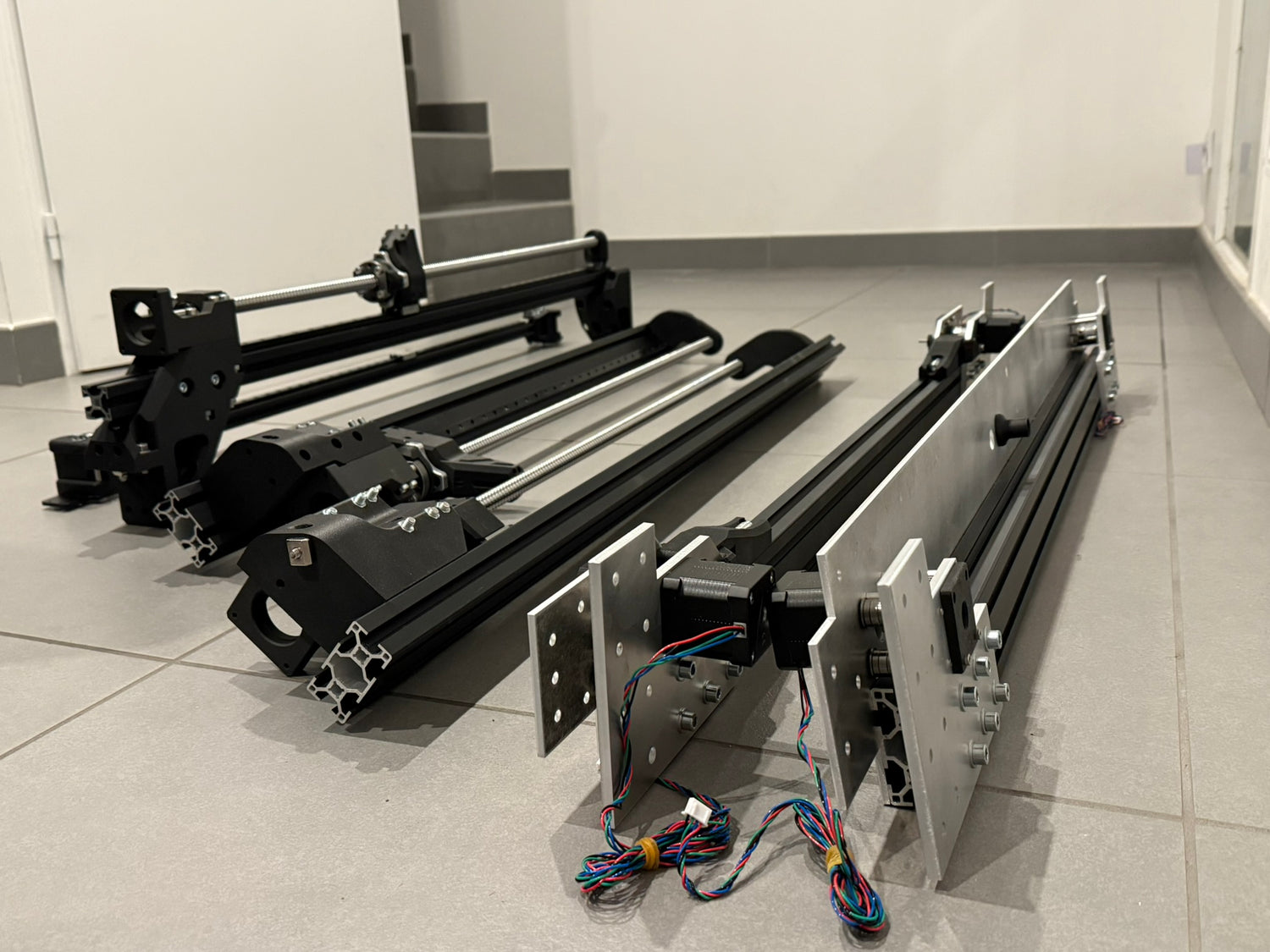

5x parts modular machine

-Gantry premade and tuned

-Easiest shippment

-Easiest logistics

What is inside this machine?

Toolhead

-VZ aluminium carriage

-Mellow Goliath Hotend

-Moons Nema + VZ extruder

-Custom PA12CF15 Duct

-Mellow CPAP unit

Frame

-3060 full aluminium frame with custom aluminium corner plates

-SFU1605 900mm with WobbleX

-Optical endstops

-Full metal gantry

-Gates GT2 belt HT

-PA12CF15 Fiberlogy Parts set

-Keenovo 600W x4

-LDO-42STH48-2504AC x4

-LDO-57STH56 x3

Electronic

-BTT Manta M8p V2

-CMA 8Go Emmc 32Go

-450W Meanwell PSU

-CPAP

-Klicky probe / Cartographer scanner

Innovations

Prebuilt and pretuned Gantry plane, ultra rigid frame and modular for maintenance, upgrade and for shipping

Bed assembly

Here we start with the bed adaptation, The biggest challenge, the biggest point of attention: 4x 8x430mm cast toolplates on a 2020 spring tuned frame to allow a precise correction. I choosed 4 silicone heater mat from Keenovo, 600 W each linked in parallel.

One thing I have learn here, past 600mm, the bed need to be fixed at to bottom, like the Voron structure, a note to a future me.

Frame Construction

Learned from the previous Vulcain prototype, I used 30x60 alumium extrusions with a blind join mounting, giving me a quick and effective squareness.

Everything is then reinforced with hiden corners, small corners, and this time I have added custom aluminium plate to reinforces all corners, and this will be used as mount for the whole harfware

Those added a tremendous stiffness.

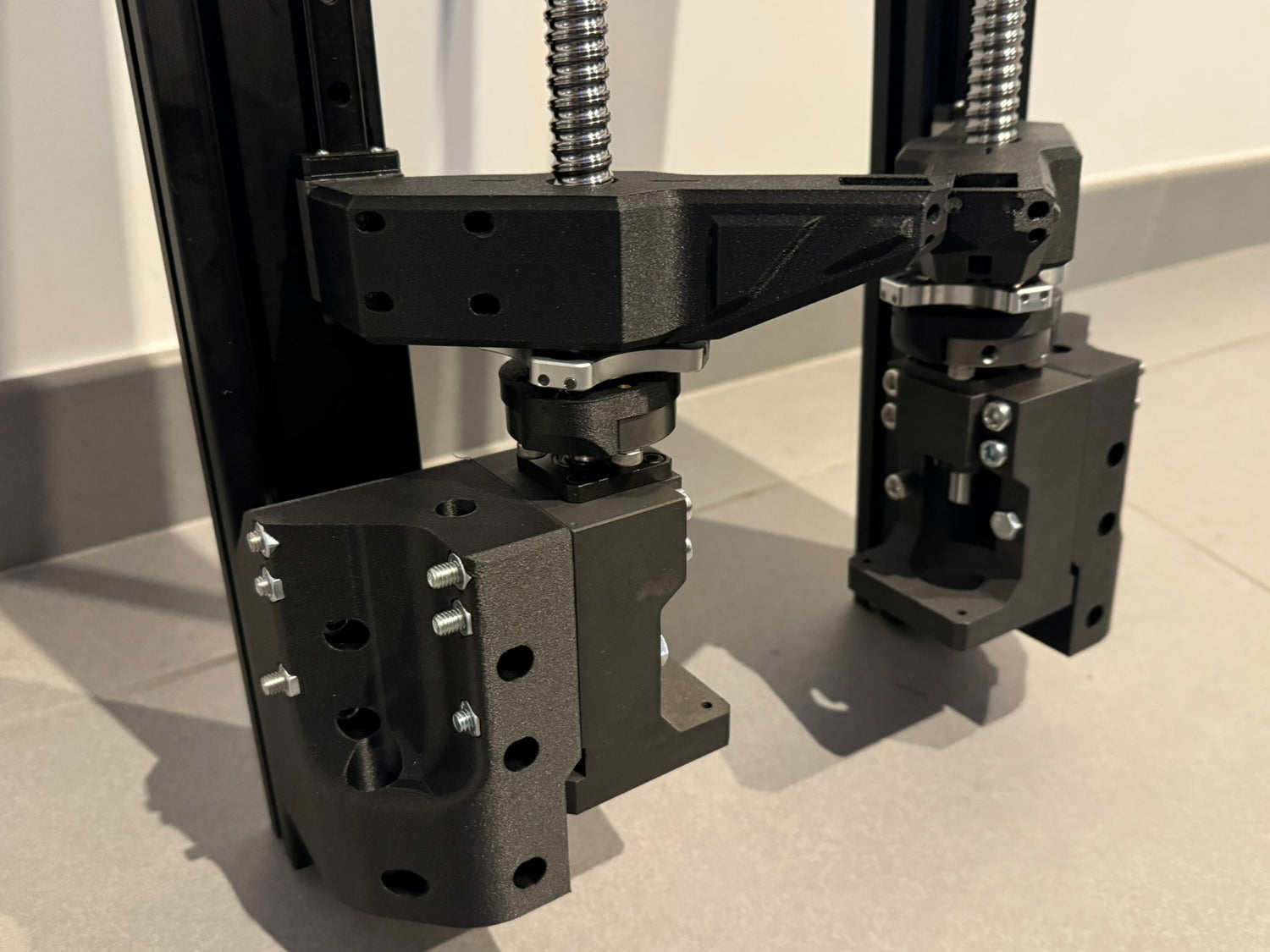

Z-System

For this build, since the bed is 28Kg almost; 1605 ballcrew with Nema 23 motor were choose

WobbleX WS16 were indicated here.

On this system, I have used HM12-57 motor mount to simplify the system

As I underestimated the mandatory holding torque of the NEMA, I have then developped a passive brake system to help me with the possible bed falling situation

This system have been already tested with a customer need, the system is simple and effective.

BRS-AWD CNC HD

AWD make sense here since we want to have a good acceleration and relay over the belt lenghts

Here the system is all metal, almost, and fully integrated in the gantry frame section

(This product will be derivated in the same spirit for VC4 and VC 3.1 in a near future)